Blog

Master the Cannabis Product Testing Process in 2025

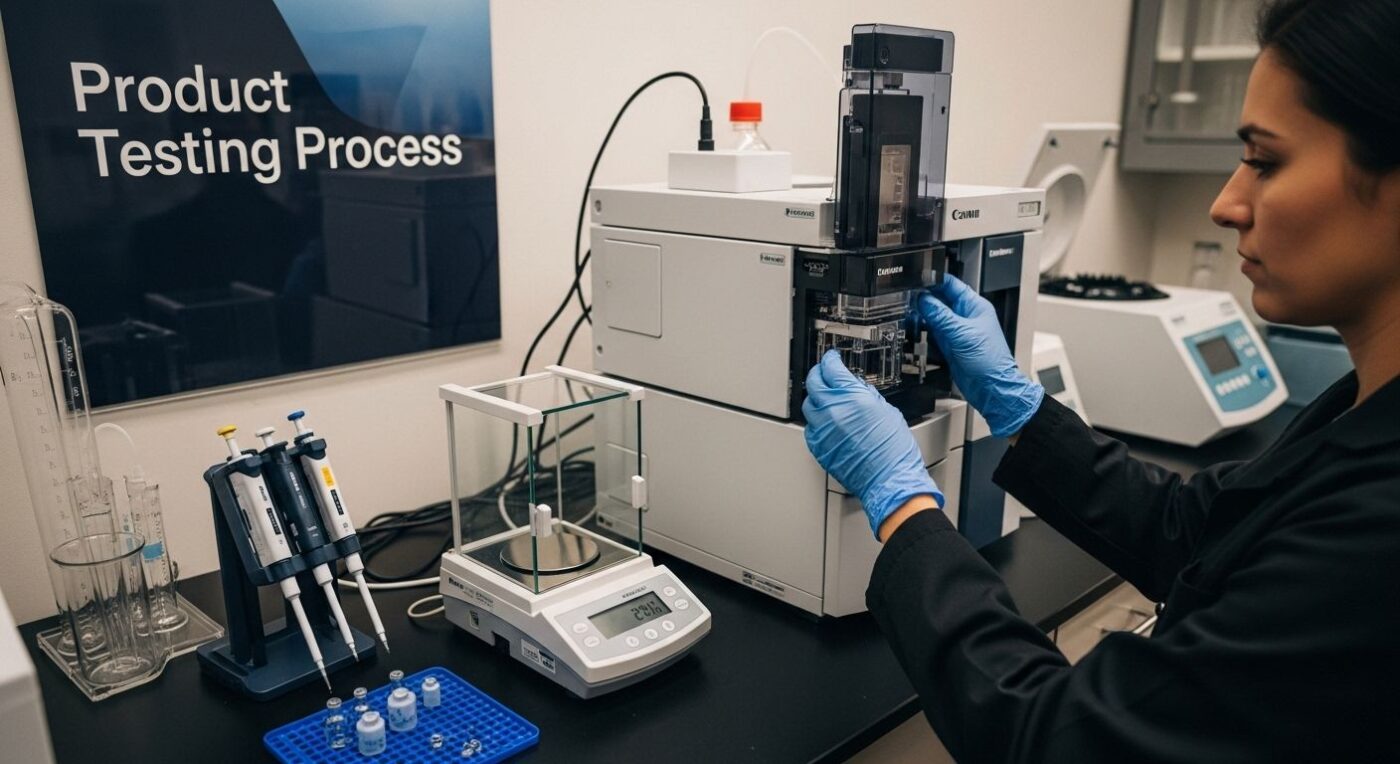

Cannabis product testing sounds intimidating with all the scientific gear and strict rules involved. Yet, despite the high-tech equipment like HPLC and GC-MS systems that can detect contaminants down to parts per billion, the real challenge is not about running fancy machines. The surprise is how much precision and preparation in simple areas like sample handling and documentation can impact accuracy far more than expensive gadgets alone.

Table of Contents

- Step 1: Gather Essential Testing Equipment And Supplies

- Step 2: Prepare Samples For Analysis

- Step 3: Conduct Laboratory Testing Procedures

- Step 4: Analyze Testing Results Thoroughly

- Step 5: Verify Quality And Compliance Standards

Quick Summary

| Key Point | Explanation |

|---|---|

| 1. Precision Equipment Is Essential | Invest in high-quality, calibrated laboratory instruments to ensure accurate and reliable cannabis testing outcomes. |

| 2. Ensure Sample Hygiene and Consistency | Maintain sterile conditions and follow strict procedures to prevent contamination and ensure uniformity during sample preparation. |

| 3. Adhere to Testing Protocols Reliably | Follow standardized methodologies and document every step to produce consistent, reproducible analytical results. |

| 4. Contextualize and Analyze Results Thoroughly | Interpret data in relation to regulatory standards, ensuring that each measurement is meaningful in safety and compliance assessments. |

| 5. Comply with Regulatory Standards Rigorously | Verify that final results align with legal requirements and implement internal reviews to uphold quality control throughout the testing process. |

Step 1: Gather Essential Testing Equipment and Supplies

Successful cannabis product testing begins with assembling a comprehensive and precise collection of scientific equipment designed to deliver accurate analytical results. The initial step in the cannabis product testing process involves carefully selecting specialized tools and supplies that meet rigorous industry standards and regulatory requirements.

Professional cannabis testing demands sophisticated laboratory equipment capable of delivering precise measurements and comprehensive analysis. Your core testing arsenal will include several mission-critical instruments: high-performance liquid chromatography (HPLC) systems for cannabinoid profiling, gas chromatography mass spectrometry (GC-MS) equipment for detecting potential contaminants, and calibrated analytical balances capable of measuring minute quantities with extraordinary precision.

Key equipment for a professional cannabis testing setup should encompass:

- Precision analytical balance (accurate to 0.0001 grams)

- Multiple micropipettes with variable volume ranges

- Temperature-controlled centrifuge

- Spectrophotometer for chemical concentration analysis

- Clean room or laminar flow hood

- Multiple sets of calibrated glassware

- Personal protective equipment (lab coats, gloves, safety glasses)

Quality control represents another crucial dimension of equipment preparation. According to NIST, laboratories must implement comprehensive measurement services and develop fit-for-purpose analytical methodologies. This means investing in reference materials, standard solutions, and calibration tools that ensure consistent and reproducible testing protocols.

Beyond technical instruments, your testing environment requires meticulous preparation. Establish a dedicated workspace with controlled temperature, minimal environmental contamination, and appropriate ventilation. Proper lighting, stable electrical connections, and protection from external vibrations will significantly enhance testing accuracy.

Successful equipment procurement isn’t just about purchasing expensive machinery. It demands understanding each instrument’s specific capabilities, maintenance requirements, and calibration protocols. Research manufacturer specifications, attend professional training sessions, and consider consulting experienced laboratory managers who can provide nuanced insights into equipment selection and optimization.

Final verification involves systematically checking each piece of equipment for proper functionality, calibration accuracy, and compliance with current regulatory standards. Document every instrument’s serial number, calibration date, and maintenance history to maintain comprehensive laboratory records and ensure ongoing quality assurance.

Step 2: Prepare Samples for Analysis

Sample preparation represents a critical gateway in the cannabis product testing process, transforming raw materials into precisely measured and scientifically viable specimens for comprehensive analysis. This foundational step demands meticulous attention to detail, ensuring that every subsequent analytical procedure yields reliable and reproducible results.

Contamination prevention emerges as the paramount concern during sample handling. Laboratory professionals must establish a sterile workspace, utilizing clean instruments and wearing appropriate personal protective equipment to minimize external interference. Selecting an appropriate sample grinding mechanism becomes essential a ceramic or stainless steel mill designed specifically for botanical materials will provide consistent particle size without introducing metallic contaminants.

Key preparation considerations include:

- Maintaining consistent sample temperature

- Using calibrated precision instruments

- Preventing cross-contamination between samples

- Documenting every preparation step meticulously

- Ensuring uniform sample homogenization

The homogenization process requires strategic approach. Begin by thoroughly mixing the cannabis sample to create a representative subset that accurately reflects the entire batch. According to ASTM International standards, proper sample preparation directly influences measurement accuracy and reduces analytical uncertainty. Grinding techniques must balance mechanical efficiency with thermal sensitivity, avoiding excessive heat that could degrade cannabinoid compounds.

Weighing represents another critical sub-stage of sample preparation. Utilize an analytical balance capable of measuring to 0.0001 grams, ensuring precise quantification. Transfer small, consistent sample quantities into clean extraction vessels, maintaining a systematic approach that allows for reproducible testing protocols. Implement a methodical labeling system that tracks each sample’s origin, weight, and unique identifier throughout the analytical workflow.

Environmental control plays a significant role in maintaining sample integrity. Regulate ambient temperature and humidity within the preparation area, protecting sensitive cannabis materials from degradation. Store samples in light-resistant, airtight containers when not actively being processed, and work efficiently to minimize exposure to potential contaminants or atmospheric variations.

Final verification involves a comprehensive checklist: confirm sample homogeneity, validate weight measurements, document preparation conditions, and ensure all samples are properly labeled and ready for subsequent analytical procedures. By executing these preparation protocols with scientific precision, you establish a robust foundation for accurate cannabis product testing.

This checklist table outlines the critical items to verify before moving cannabis samples to the analysis phase, ensuring accuracy, compliance, and reproducibility throughout your testing process.

| Preparation Task | Verification Criteria | Completed (Yes/No) |

|---|---|---|

| Confirm Sample Homogeneity | Even consistency without clumping | |

| Validate Weight Measurement | Accurate to 0.0001 grams | |

| Document Preparation Steps | All procedures and conditions recorded | |

| Ensure Proper Labeling | Source, batch, and unique ID attached | |

| Check Environmental Controls | Temperature and humidity regulated | |

| Secure Sample Storage | Stored in light-resistant, airtight container | |

| Clean Work Area and Tools | No contaminants or residues present |

Step 3: Conduct Laboratory Testing Procedures

Conducting comprehensive laboratory testing procedures represents the most intricate and scientifically demanding phase of cannabis product analysis. This critical stage transforms meticulously prepared samples into a detailed chemical profile that reveals the product’s complete compositional landscape.

Analytical methodologies form the backbone of precise cannabis testing. Multiple sophisticated instruments will simultaneously evaluate different aspects of the cannabis sample, creating a multidimensional assessment of its chemical composition. High-performance liquid chromatography (HPLC) becomes instrumental in quantifying precise cannabinoid concentrations, while gas chromatography mass spectrometry (GC-MS) helps detect potential contaminants with extraordinary sensitivity.

Key testing parameters include:

- Cannabinoid potency profile

- Terpene composition

- Pesticide screening

- Heavy metal contamination

- Microbial impurity detection

- Residual solvent analysis

Precision demands strict protocol adherence. Each testing procedure requires carefully calibrated equipment, standardized methodology, and meticulous documentation. Technicians must maintain consistent environmental conditions, managing temperature, humidity, and potential cross-contamination risks throughout the analytical process. Instrument calibration becomes paramount, ensuring every measurement represents an accurate representation of the sample’s true chemical characteristics.

According to California Department of Cannabis Control, comprehensive testing must cover multiple dimensions beyond basic cannabinoid analysis. This holistic approach protects consumer safety by identifying potential biological or chemical hazards that might compromise product quality. Laboratories must maintain rigorous quality control standards, utilizing validated testing methods that provide reproducible and defensible results.

The testing workflow progresses systematically through sequential analytical techniques. Initial screenings determine overall cannabinoid content, followed by more specialized tests targeting specific potential contaminants. Terpene profiling offers insights into the product’s potential therapeutic or recreational characteristics, while contaminant screening ensures compliance with stringent health and safety regulations.

Documentation represents the final critical component of laboratory testing. Every measurement, observation, and analytical result must be meticulously recorded, creating a comprehensive report that provides transparent insights into the cannabis product’s complete chemical profile. Laboratories must maintain detailed logs that track instrument performance, calibration records, and individual test results, establishing a robust chain of scientific evidence.

Successful completion of laboratory testing procedures requires unwavering attention to detail, scientific rigor, and a commitment to producing reliable, reproducible analytical results that meet the highest industry standards.

Step 4: Analyze Testing Results Thoroughly

Analyzing testing results transforms raw data into meaningful insights that determine a cannabis product’s safety, quality, and compliance. This critical stage bridges scientific measurement with actionable intelligence, requiring a systematic and nuanced approach to interpreting complex analytical findings.

Data interpretation demands more than simple numerical review. Professionals must contextualize each measurement against established regulatory standards, understanding the intricate relationships between different chemical components. Cannabinoid potency, terpene profiles, contaminant levels, and potential impurities must be evaluated holistically, recognizing how individual measurements collectively represent the product’s overall characteristics.

Key analytical considerations include:

- Comparing results against legal compliance thresholds

- Identifying potential chemical interactions

- Assessing statistical significance of measurements

- Recognizing patterns across multiple test parameters

- Evaluating measurement uncertainty

Statistical analysis becomes paramount in transforming raw data into reliable conclusions. Calculate standard deviations, confidence intervals, and comparative metrics that provide robust scientific context. Measurement uncertainty represents a crucial factor professional analysts must address, understanding that no scientific measurement is perfectly precise. Sophisticated statistical techniques help quantify potential variations and establish meaningful confidence ranges for each test result.

According to Washington State Liquor and Cannabis Board, comprehensive result analysis extends beyond numerical assessment. Laboratories must develop comprehensive reporting frameworks that clearly communicate test findings, potential risks, and compliance status. This involves creating detailed documentation that translates complex scientific data into accessible, actionable information for regulators, producers, and consumers.

Cross-referencing results against multiple testing standards ensures comprehensive evaluation. Compare findings with internal laboratory benchmarks, state regulatory requirements, and industry best practices. Look for potential anomalies or unexpected variations that might indicate sampling errors, equipment calibration issues, or genuine product variations. Each deviation from expected parameters requires careful investigation and potential retesting.

Technological tools play a significant role in modern result analysis. Advanced data visualization software can transform complex datasets into intuitive graphical representations, helping analysts quickly identify trends, outliers, and potential areas of concern. Machine learning algorithms increasingly support data interpretation, providing predictive insights and supporting more nuanced analytical approaches.

Successful result analysis culminates in a comprehensive report that provides transparent, scientifically rigorous insights into the cannabis product’s complete chemical profile. This document serves as a critical tool for ensuring product safety, regulatory compliance, and consumer protection.

Step 5: Verify Quality and Compliance Standards

Verifying quality and compliance standards represents the final critical gateway in the cannabis product testing process, transforming analytical data into a definitive assessment of product safety and regulatory adherence. This comprehensive verification ensures that every tested cannabis product meets stringent legal and scientific requirements before reaching consumers.

Regulatory alignment emerges as the cornerstone of this verification process. Laboratories must meticulously cross-reference test results against multiple layers of compliance standards, including state-specific regulations, federal guidelines, and industry best practices. Each measurement must fall within precisely defined acceptable ranges for cannabinoid content, contaminant levels, and potential impurities.

Key verification criteria include:

- Confirming cannabinoid concentration limits

- Validating pesticide and heavy metal thresholds

- Ensuring microbial safety standards

- Checking moisture content specifications

- Verifying terpene profile consistency

Documentation becomes an essential component of the compliance verification process. Create comprehensive reports that transparently demonstrate how each test result aligns with regulatory requirements. These documents must include detailed methodology descriptions, measurement uncertainties, and explicit comparisons against established standards. Traceability represents a critical element technical experts must maintain, ensuring every data point can be reliably tracked and verified.

According to Reuters reporting, inconsistent testing standards across different jurisdictions create significant challenges for cannabis producers. Successful verification requires a nuanced understanding of regional regulatory variations, adapting testing protocols to meet diverse compliance landscapes.

Quality control protocols extend beyond simple numerical compliance. Laboratories must implement rigorous internal review processes that challenge and validate initial test results. This might involve duplicate testing, cross-referencing with alternative analytical methods, and conducting comprehensive uncertainty assessments. Professional analysts should approach verification as a holistic scientific investigation, not merely a bureaucratic checkbox exercise.

Technological tools play an increasingly sophisticated role in compliance verification. Advanced data management systems can automatically flag potential regulatory discrepancies, highlight measurement anomalies, and generate comprehensive compliance reports. Machine learning algorithms are emerging as powerful allies, helping laboratories develop more nuanced and predictive compliance assessment frameworks.

Successful verification culminates in a definitive determination: whether the cannabis product meets all required quality and safety standards. This final assessment represents the ultimate validation of the entire testing process, ensuring that only products meeting the highest scientific and regulatory standards reach consumers.

Ready for Truly Tested Cannabis? Experience Puff Laco’s Commitment to Purity

Navigating the rigorous world of cannabis product testing can feel overwhelming. You want to trust what you consume, but hearing about contamination, testing inconsistencies, and uncertainty in product quality can leave you hesitant to try new options. From maintaining strict laboratory standards to ensuring every batch meets safety requirements, the challenges are real. You deserve transparency, reliable results, and peace of mind with every purchase.

.png)

Why settle for less than verified purity? At Puff Laco, you get full confidence in every vape, pre-roll, edible, and gummy we offer. Our cannabis products undergo strict pesticide and contaminant screenings. We back every flavor-specific strain, live resin, and full spectrum extract with robust testing and a straightforward authenticity verification system. Explore our selection and experience the difference that scientific quality can make. Find your next trusted product today at Puff Laco’s online shop and discover how easy it is to choose cannabis with proven safety and real results.

Frequently Asked Questions

What equipment is essential for cannabis product testing?

Successful cannabis product testing requires specialized equipment, including high-performance liquid chromatography (HPLC) systems for cannabinoid profiling, gas chromatography mass spectrometry (GC-MS) for detecting contaminants, precision analytical balances, and various lab instruments like micropipettes and spectrophotometers.

How can I prevent contamination during sample preparation?

To prevent contamination during sample preparation, establish a sterile workspace, utilize clean instruments, wear personal protective equipment (PPE), and employ dedicated grinding mechanisms designed for botanical materials to maintain the integrity of cannabis samples.

What parameters are tested in a cannabis product analysis?

Cannabis product analysis typically tests for cannabinoid potency, terpene composition, pesticide levels, heavy metal contamination, microbial impurities, and residual solvents to ensure product safety and compliance.

How can I interpret cannabis testing results effectively?

Effective interpretation of cannabis testing results involves contextualizing measurements against regulatory standards, performing statistical analysis to gauge reliability, and cross-referencing results with industry benchmarks to identify any anomalies or compliance issues.